Mindful of energy, water, and waste management, we have adopted an integrated approach focusing on environmental protection and awareness, waste and energy reduction, and risks and opportunities related to the environment.

We are committed to maintaining the environment and reducing the footprint of our business operations by:

• Identifying, measuring, and offsetting the environmental footprint of our global operations;

• Reducing our environmental impact through local operations initiatives;

• Preventing pollution by conserving energy and resources, recycling, minimizing waste, and pursuing other resource reduction strategies;

• Maintaining full compliance with applicable environmental laws, regulations, and company policies and procedures; and

• Working with our stakeholders on activities that promote environmental protection and stewardship.

We regularly strive to identify sustainable initiatives and innovations that deliver energy and natural resource efficiency across new and existing facilities we own and manage.

For several years, we have been monitoring our facilities’ utility operating costs monthly, including electricity, natural gas, water usage, waste disposal, and carbon emissions to encourage each facility to focus on conservation measures and enhance environmental sustainability efforts. GEO’s goal is to heighten operational awareness and encourage each facility to lower utility operational costs.

The systems we have developed allow us to identify and prioritize the most impactful energy, water, and emissions reduction activities.

In 2017, we issued our first internal utility sustainability report, ranking leading and trailing facilities throughout our company in terms of electricity, gas and water usage, and solid waste generation.

The report also provided instructions and strategies to staff for reducing the consumption of energy and water resources and addressed waste production. As individual GEO facilities adopt a green operational philosophy, the facilities are better able to manage energy consumption, reduce emissions, and lower operating costs.

Starting in 2020, GEO undertook the initiative of determining our carbon footprint, including greenhouse gas (GHG) emissions and energy consumption data. We gathered data from each facility regarding energy use, including natural gas, diesel, fuel, propane, electricity, and water use; and used the data to calculate Scope 1 and Scope 2 emissions.

The initiative also helped gauge the types of recycling programs GEO’s facilities have implemented on a local level. While most of our facilities typically have recycling programs focused on wastepaper and cardboard, plastic, glass, wood, and organic waste, a number of our facilities are also engaged in recycling programs for aluminum, metals, electronics, and batteries.

The data for GEO’s Energy and Consumption Metrics shows the company’s total energy, waste, and water consumption for the year, and then breaks that data down into three segments:

• GEO Secure Services Facilities (U.S. + International)

• GEO Care Facilities (Residential Reentry)

• Corporate and Regional/Divisional Offices

Our baseline year is 2019 and The GHG Protocol: A Corporate Accounting and Reporting Standard, Revised was used in the calculation of energy use and GHG emissions. Energy emission factors are obtained from the International Energy Agency’s 2024 Emissions Factors, Department for Energy Security and Net Zero (DESNZ) 2024 emissions factors, the U.S. Environmental Protection Agency’s (EPA’s) Emissions & Generation Resource Integrated Database (eGRID) publication released January 2025 and the EPA’s Emissions Factors for Greenhouse Gas Inventories released January 2025.

All energy sources are included in intensity calculations. All seven gases identified by the GHG Protocol are included and relevant gases based on GEO operations include CO2, CH4, N2O, and HFCs. Global warming potentials are obtained from the Intergovernmental Panel on Climate Change (IPCC) Sixth Assessment Report.

The data for GEO's Energy and Consumption Metrics can be found in GEO's annual Corporate Responsibility Highlights disclosure.

Year End Company Wide Savings:

EXAMPLE OF UTILITY COST SAVING:

Joe Corley Processing Center:

Facility improvements include push button fixtures, lighting replacement, and air conditioning automatically turns off when room doors open. SAVINGS OF 14%

As part of GEO’s efforts to reduce consumption and achieve both cost and energy efficiency, we have augmented our transportation fleet with hybrid vehicles. Over the last five years we have invested approximately $1.5 million to add nearly 50 hybrid vehicles to our existing transportation fleet. The hybrid vehicles are primarily used at GEO Secure Services Facilities for perimeter surveillance and security and are used at low speeds which results in a greater use of electric battery power as opposed to the combustion engine. The low speeds on the internal combustion engines prevents ash from burning. The hybrids do not have to worry about this due to the use of battery electric power at low speeds.

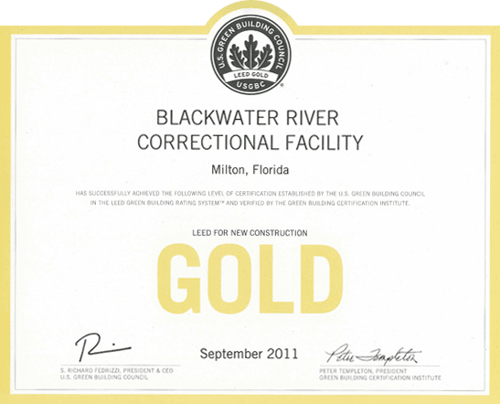

For several years, GEO has incorporated industry-leading sustainability standards in the development of new facilities. In October 2011, Blackwater River Correctional and Rehabilitation Facility, located in Milton, Florida, became GEO’s first Leadership in Energy and Environmental Design (LEED) Certified project to receive a Gold Certification. Since the development of the Blackwater River Correctional and Rehabilitation Facility, ten new or expanded GEO facilities have been designed to LEED certification standards or the international equivalent.

LEED certification is based on an evaluation of a number of environmental factors including but not limited to the sustainability of the site, the efficient use of water, energy, material and other resources, the quality of indoor air and overall environment, and the use of innovative and environmentally friendly technologies and strategies.

The LEED certification program is administered by the Green Building Certification Institute. The Green Building Certification Institute determines that a completed project satisfies all prerequisites and has achieved a minimum number of points outlined in the LEED for the rating system to achieve a particular level of LEED certification, such as LEED Certified, LEED Silver, LEED Gold or LEED Platinum.

New or expanded GEO Facilities designed to LEED silver standards or the international equivalent:

New or expanded GEO facilities designed to LEED standards:

BI continually looks for new ways to be operationally aware when it comes to the disposal of materials. The majority of equipment orders are shipped in plastic cases, which are durable and can be reused four to five times longer than previous cardboard shipping containers. Packaging for supplier parts also contains recycled content. BI has a shipping carton return service in place for all customers.

BI developed a “Greenville” station within manufacturing to recycle, repair, and reuse plastic products. BI has initiated various energy efficiency programs including the installation of energy efficient lighting. We buy products that are free from Ozone Depleting Chemicals (ODCs), lead, and other harmful substances.

BI voluntarily complies with two major directives, the Waste Electrical and Electronic Equipment Directive (WEEE) and the Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment (RoHS). Both WEEE and RoHS became European Law in February 2003.

WEEE is the European Community directive on waste electrical and electronic equipment that sets collection, recycling, and recovery targets for all types of electrical goods. WEEE aims to minimize the impact of these goods by increasing re-use and recycling to reduce the amount going to landfills. The directive places the responsibility for the collection, treatment, and disposal of waste electrical and electronic equipment on the manufacturers of such equipment. Distributors are required to allow consumers to return their waste equipment free of charge. RoHS bans placing new electrical and electronic equipment that contains more than the agreed levels of lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyl (PBB), and polybrominated biphenyl ether (PBDE) flame retardants in the European market.